What is PEB?

During the 1960s, standardized engineering designs for buildings were first marketed as PEBs. Historically, the primary framing structure of a pre-engineered building is an assembly of I-shaped members, often referred as I-beams. In pre-engineered buildings, the I beams used are usually formed by welding together steel plates to form the I section. The I beams are then field-assembled (e.g. bolted connections) to form the entire frame of the pre-engineered building. Taper the framing members (varying in web depth) according to the local loading effects. Larger plate dimensions are used in areas of higher load effects.

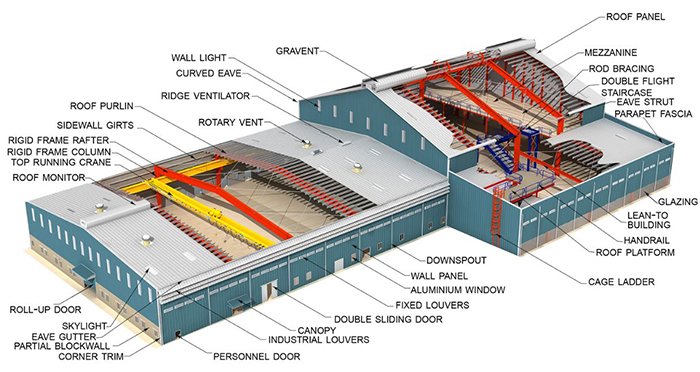

Cold formed Z- and C-shaped members may be used as secondary structural elements to fasten and support the external cladding. Roll-formed profiled steel sheet, wood, tensioned fabric, precast concrete, masonry block, glass curtain wall or other materials may be used for the external cladding of the building.

In order to accurately design a pre-engineered building, engineers consider the clear span between bearing points, bay spacing, roof slope, live loads, dead loads, collateral loads, wind uplift, deflection criteria, internal crane system and maximum practical size and weight of fabricated members. While pre-engineered buildings can be adapted to suit a wide variety of structural applications, the greatest economy will be realized when utilizing standard details. An efficiently designed pre-engineered building can be lighter than the conventional steel buildings by up to 30-40%. Lighter weight equates to less steel and a potential price savings in structural framework.